Cleaning each layer of precious metal.

Each layer is cleaned before being staked into a billet. This is the most important stage of the process, it helps the fusing and prevents the billet from cracking when it is being forged.

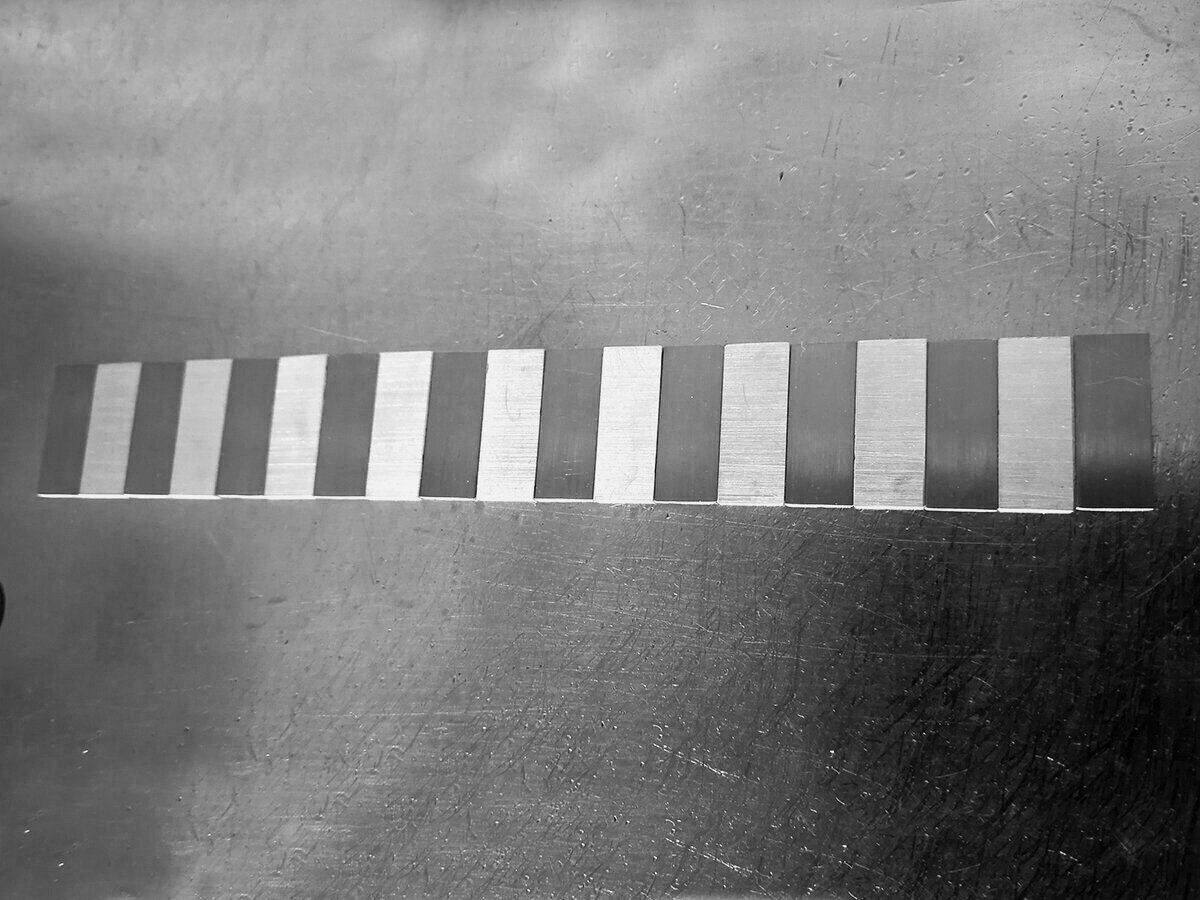

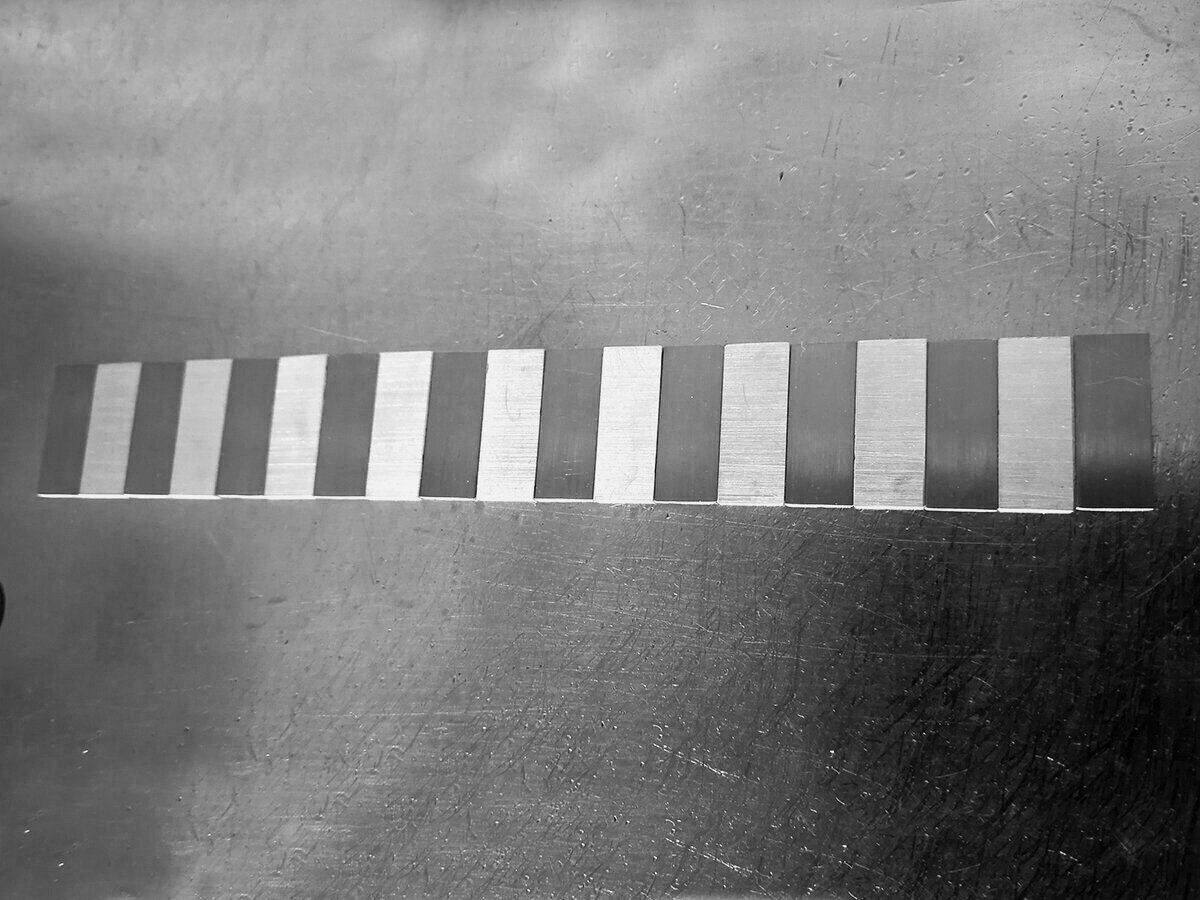

The layers of precious metal.

The layers of precious meta laid out in order before being cleaned.

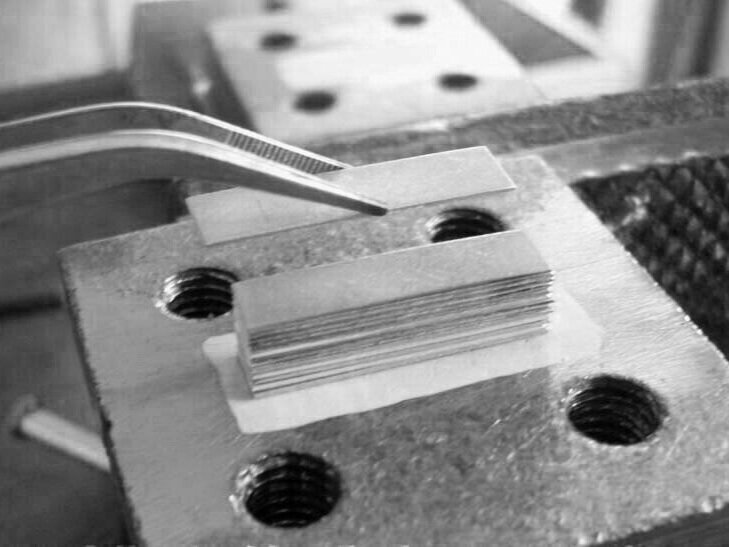

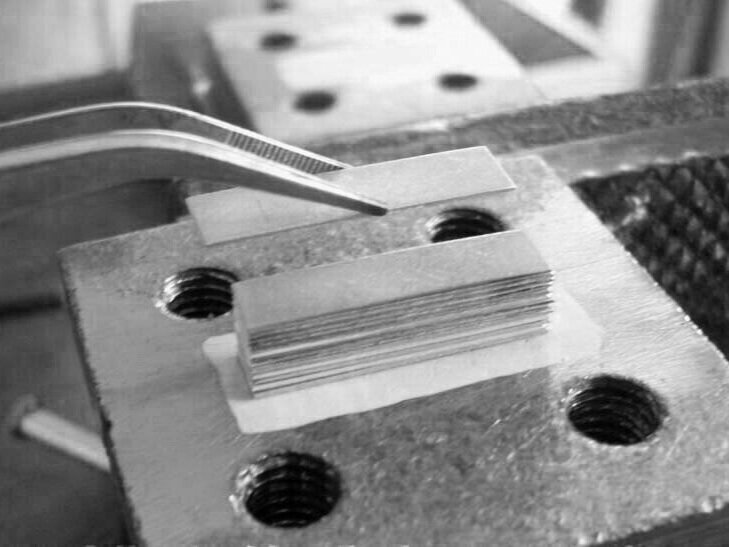

Stacking the billet

Each layer of precious metal is stacked in order then clamped forming a billet, this is then kiln fired for up to 90 minutes for the fusing process.

Annealing the metal.

The billet must be regularly annealed so that the metal is softened, this allows it to be forged and patterned.

Forging the billet

The forging is part of process that creates the pattern of each ring blank. The nature of this process individualises each and every blank.

Rolling the forged billet

Nearing the final stage of the crafting of the ring blank. Rolling the forged billet to the required length.

The patterning of the billet is complete and ready to be turned into a ring.